Menü

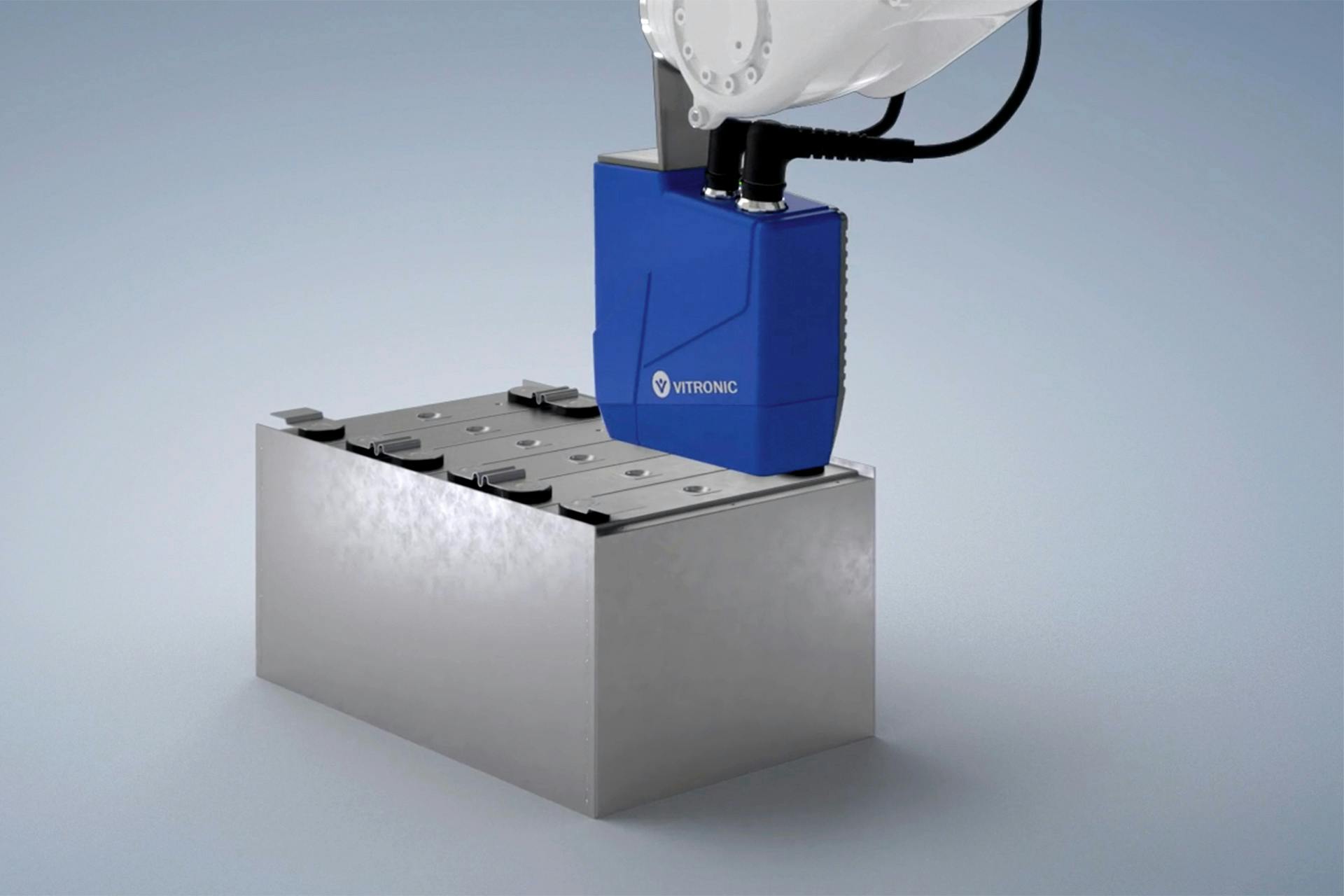

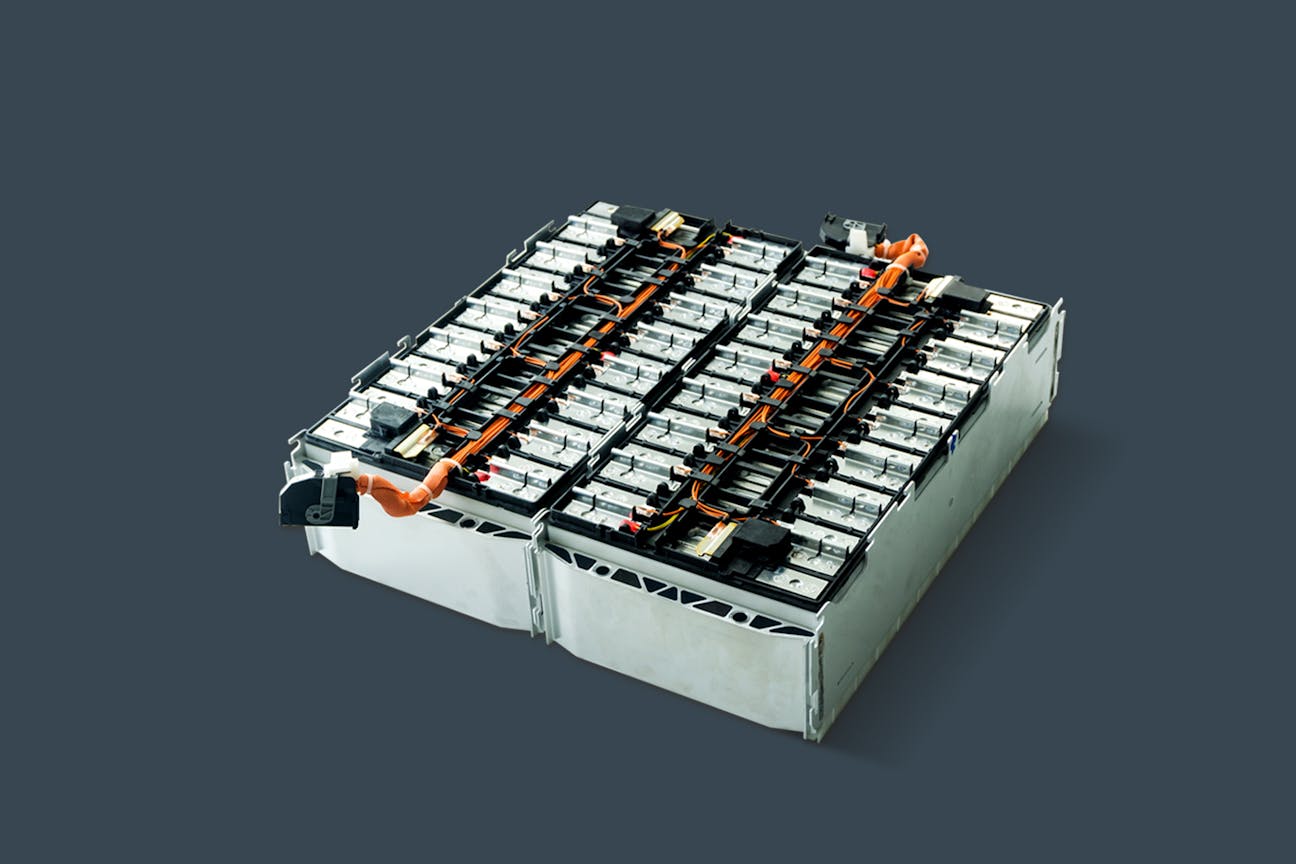

Weld Seam Inspection in Battery Production Increasing market share with quality & performance

Premium Li-Ion Batteries Thanks to Weld Seam Inspection

Weld Seam Inspection in Battery Production

For Taking Away and Passing On

Brochure

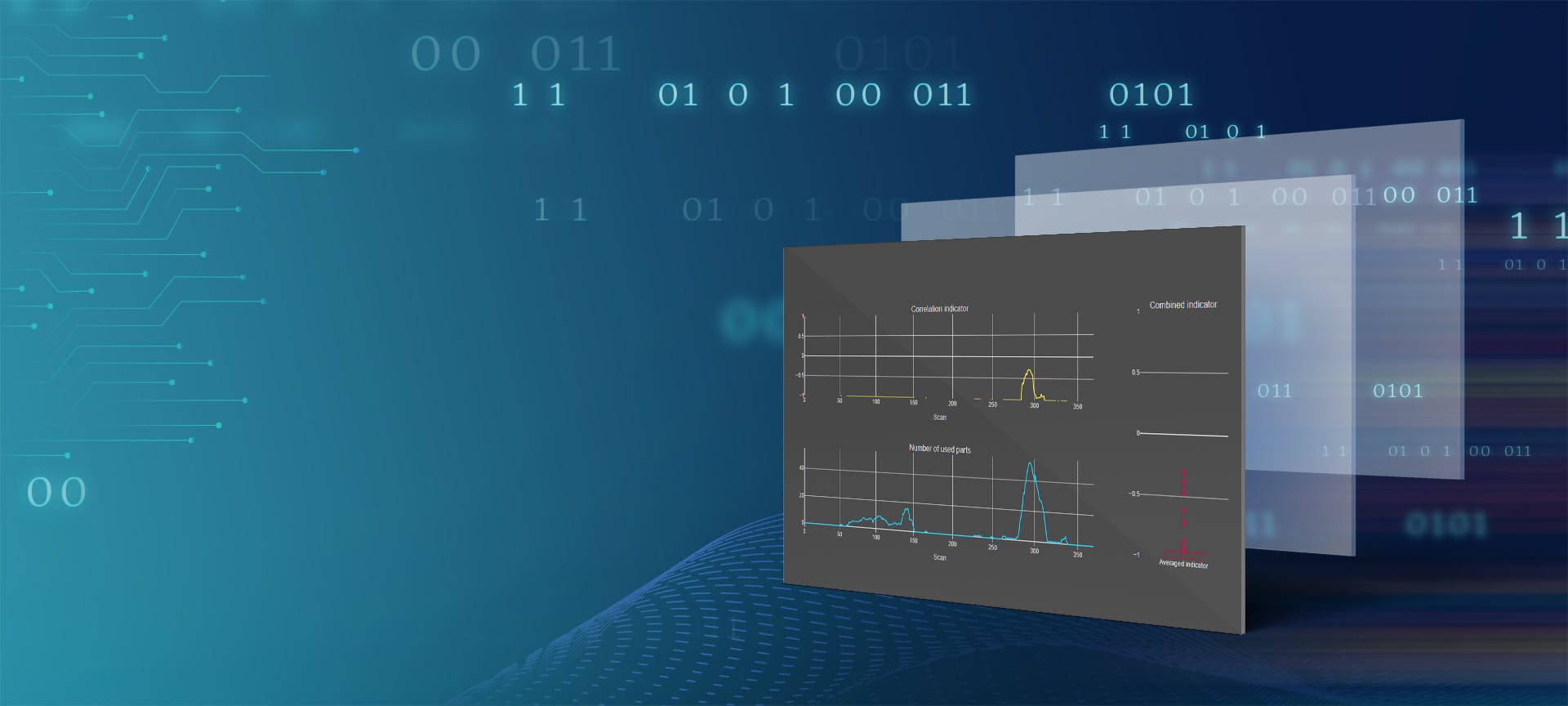

Quality assurance and process optimization for your battery production

Brochure

VIRO WSI - Instead of recalls: Automatic weld seam inspection